In today’s fast-paced consumer market flexible pouch packaging is a go-to option for brands across multiple sectors. From pet food and snacks to personal care products and sauces, pouches are easy to use, light, and sustainable. But how do you make the leap from idea to perfectly designed pouch packaging that halts traffic, protects your product, and speaks to your brand?

We’ve been helping companies design and build high-performance pouch packaging at Stanley since 1998. In this blog, here, we’ll walk you through the most important steps and considerations to follow when designing pouch packaging—from start to finish.

Step 1: Understand Your Product and What It Requires

Every great pouch packaging design begins with a deep understanding of your product. Ask yourself:

- What is the physical shape of the product—solid, liquid, powder, granular?

- What shelf life do you anticipate, and to what environmental hazards (light, oxygen, moisture, etc.) is it exposed?

- Will it be exposed to freezing, heat, or long-distance transport?

- Do you require resealing or easy-open convenience?

These questions will determine the type of materials, pouch shape, and sealing technology you will need.

At Stanley, our experienced engineers will help you define your product characteristics and guide you through the optimum protective materials and structures to ensure freshness, safety, and compliance.

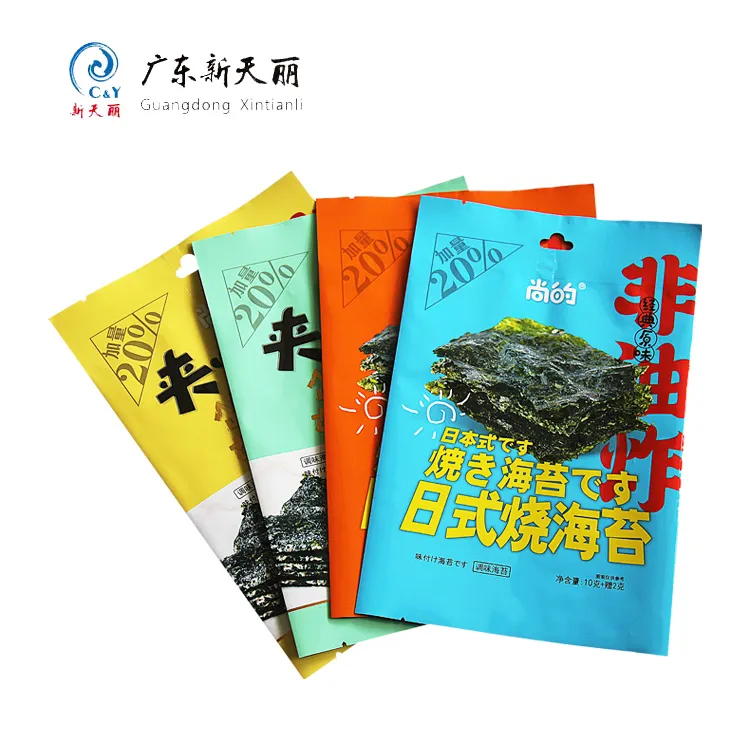

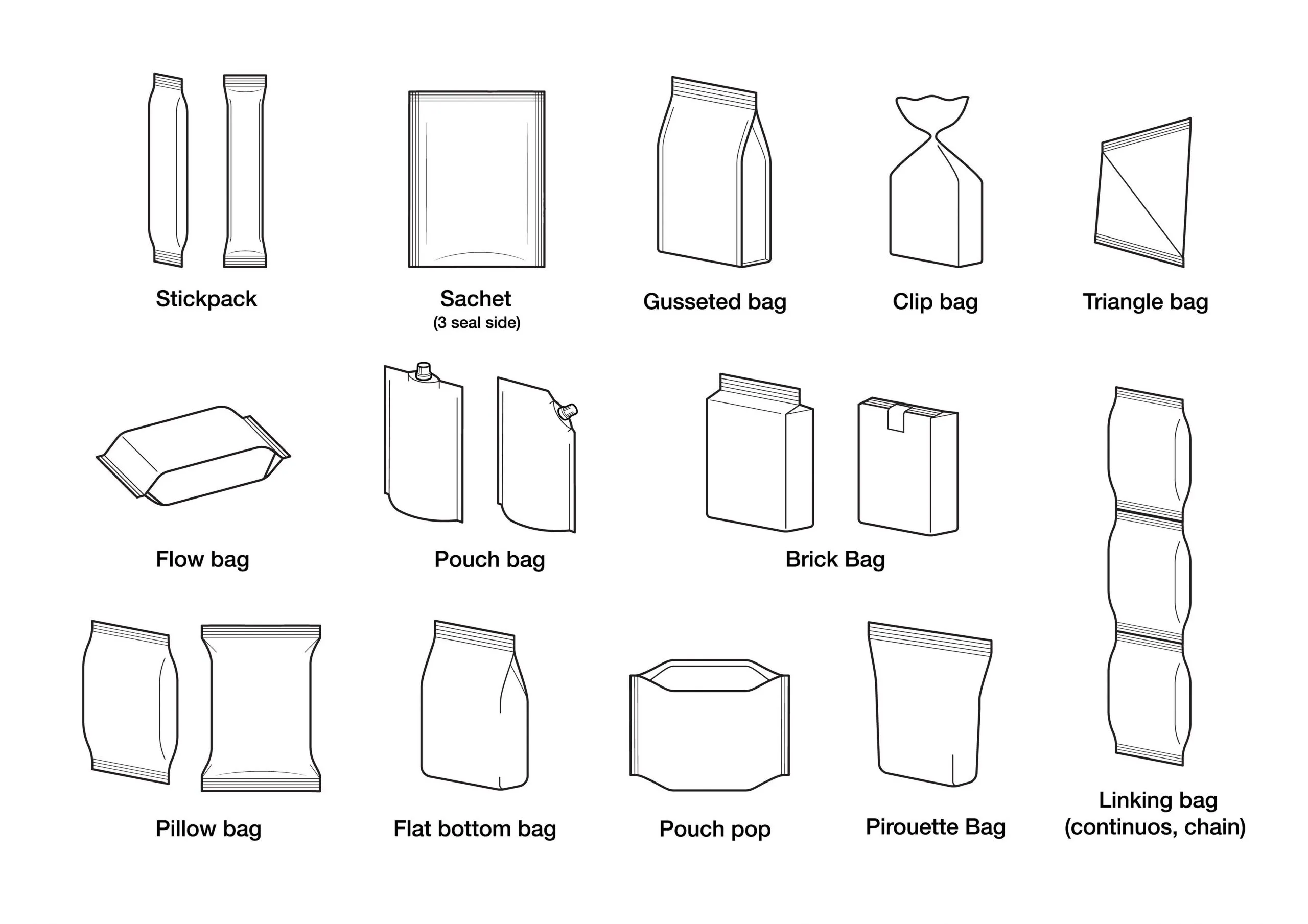

Step 2: Choose the Perfect Pouch Format

The structure of your pouch packaging will have a strong impact on both user experience and visual appeal. The pouch formats that are most frequently used are:

▸ Stand-Up Pouches (SUP)

The most dramatic and versatile format. Perfect for shelf presentation with generous space for branding.

▸ Flat or 3-Side Seal Pouches

Simple and cost-effective, ideal for single-use or sample-sized products.

▸ Spouted Pouches

Excellent for liquid or semi-liquid foods like juices, sauces, or baby food. Easy to pour and reseal.

▸ Quad-Seal or Side-Gusseted Pouches

Good for heavier product (like pet food or coffee), offering great stability and a high-end appearance.

▸ Shaped Pouches

Custom die-cut designs that follow brand mascots, product shapes, or create ergonomic experiences.

Our design team at Stanley can prototype and recommend the ideal pouch packaging shape that fits your product category, brand image, and retail strategy.

Step 3: Select Barrier Films and Materials

The choice of the right packaging film is necessary in order to maintain the integrity of your product. Some of the common structures are:

- PET/PE or BOPP/PE laminates – commonly used for snacks and dry goods

- PET/Aluminum/PE – for high-barrier needs such as powders or products sensitive to light and oxygen

- Kraft Paper Laminates – for a natural, eco-conscious appearance

- Mono-material recyclable films – for brands targeting sustainability and recyclability

At Stanley, we have a wide range of material couples and continue to invest in green, recyclable, and compostable solutions for brands with sustainability goals.

Step 4: Focus on Functional Features

A pouch must be easy to use, store, and dispose of. Functional elements to consider include:

- Zippers and Velcro closures for resealability

- Tear notches and laser scoring for smooth opening

- Spouts and caps for liquid products

- Hang holes or euro slots for point-of-sale display

- Valves for gas release in coffee or fermented foods

Our product design group can incorporate these features effectively without compromising cost-effectiveness and appearance.

Step 5: Create a Compelling Graphic Design

Your pouch packaging is normally the first touch a client has with your brand. Make it significant by:

- Showing your logo and product name clearly

- Using color psychology and imagery that evoke trust, hunger, or lifestyle

- Ensuring all necessary information (ingredients, certifications, usage instructions) is readable and compliant

- Leaving adequate “white space” to prevent visual clutter

- Thinking about printing method—rotogravure, flexo, or digital

Stanley provides high-res mockups and collaborates with expert pouch packaging designers to transform your concept into a production-quality work of art.

Step 6: Validate with Prototypes and Testing

Before you move to large-scale production, conduct the following tests:

- Drop and compression tests to check durability

- Heat seal strength testing to ensure proper closure

- Leakage and vacuum tests for liquid pouches

- Barrier testing to validate material protection

At Stanley, our internal quality control lab conducts intense simulations to make your pouch not just look great—but work perfectly from factory to consumer hands.

Step 7: Consider Sustainability and Environmental Compliance

Consumers today are more environmentally aware than ever before. Eco-friendly options are no longer a choice for many brands.

- Use RTO (Regenerative Thermal Oxidizer) systems to reduce emissions during manufacturing (as we do at Stanley)

- Opt for recyclable or compostable materials when possible

- Design for material efficiency to reduce waste

Stanley is proud to be a green manufacturing leader with advanced environmental management systems in place, ensuring that every pouch packaging we produce meets global sustainability benchmarks.

Why Choose Stanley as Your Pouch Packaging Partner?

Established in 1998, Stanley is a leading flexible pouch packaging manufacturer with more than 25 years of experience supplying brands in food, pet food, personal care, and household industries.

With a state-of-the-art manufacturing facility spanning more than 15,000 square meters, we are equipped with:

- Automated production lines

- Professional R&D packaging team

- Strict quality testing laboratories

- Advanced RTO systems for eco-friendly production

We’re committed to partnership, not merely production. Whether you require small-batch prototypes or high-volume, multi-layer pouch packaging with custom print, Stanley is your reliable pouch packaging partner from concept to delivery.

Let’s make your product a best-seller—one pouch at a time. Contact Stanley today to begin your pouch packaging journey.