With the fast-changing consumer goods industry today, packaging not only has been a product protective device, but also influences the product shelf life, brand value, and customer satisfaction. With all the various types of packaging, Flexible Packaging is becoming one of the fastest growing packaging forms in the world due to its extremely high degree of flexibility, efficiency, and sustainability.

Learn about Flexible Packaging

Flexible packaging is produced from flexible material (such as plastic film, foil, paper, etc.) and is characterized by the simple flexibility of packaging form. Flexible packaging contrasts with rigid packaging (such as bottles, cans) because it weighs less, is simpler to store, and is less expensive to ship. Flexible packaging is often utilized in the production of various bags, packaging film, envelopes, etc.

Common Types of Flexible Packaging

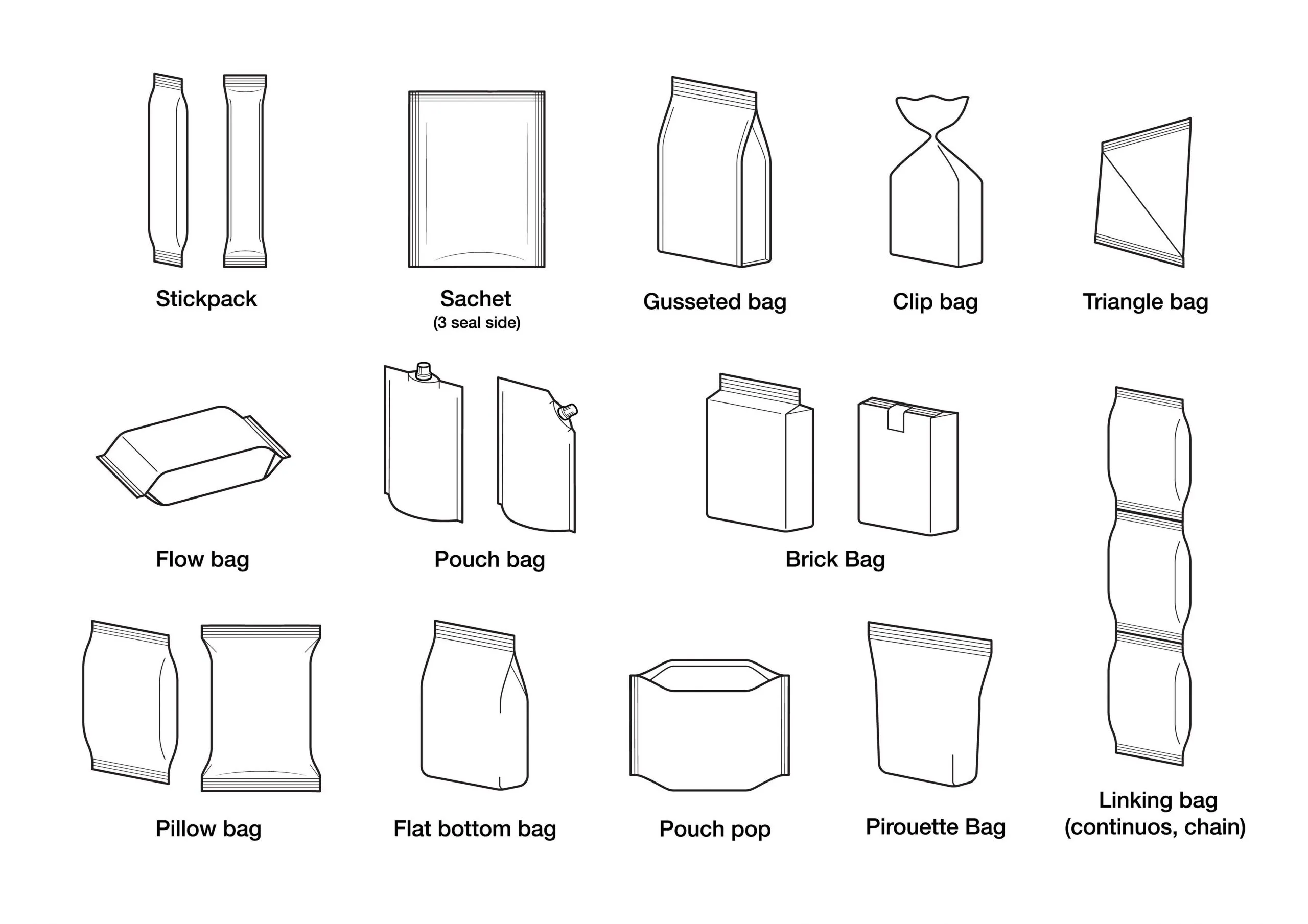

Stand-up Pouches: The bottom of the stand-up pouch has a support structure and can stand on its own. It is best to showcase on the shelf. It is generally used for snacks, beverages, pet foods, etc.

Flat Pouches / Sachets: Flat Pouch is of minimalist design, cost-effective and convenient, suitable for single-packaging, e.g., seasonings, snacks, facial masks and other products.

Flat Bottom Pouches: Stable structure, eight sealed edges on the bottom and sides, can be displayed upright, large capacity, and neat appearance. It is a common packaging for high-end food and pet food.

Spout Pouches: The top or side is equipped with a reusable spout for easy pouring and sealing. It is intended for liquids, sauces, baby food, etc.

Rollstock Films: It is provided in roll form for high-speed automatic packaging lines. It can be flexibly made into various bag shapes and is widely used in the food industry.

Vacuum Pouches: It can be vacuum packaged to effectively extend the shelf life. It is often used for products that need to be refrigerated, such as meat, seafood, and cooked food.

Retort Pouches: It possesses good heat resistance and can be directly heated and sterilized. It is used in packaging ready-to-eat foods and canned products, replacing the use of iron cans.

Shrink Films & Sleeves: After being heated, they are tightly wrapped around the product’s surface, placed on bottled drinks, cans, etc., to improve the appearance and serve as a tamper preventer.

Core Advantages of Flexible Packaging

Lightweight and Space-Saving: Reduce Shipping Expenses and Pressure on Storage

Compared to rigid packaging (such as glass bottles and metal cans), flexible packaging is light in weight and smaller in size, which can greatly reduce the cost of logistics in shipping and actually save storage space in the storage link. This is an especially significant advantage for e-commerce, small package goods, and brands that must be delivered regionally.

Highly Customized: Flexible Customization of Size, Shape, Material and Printing Effect

Flexible packaging has different kinds of pouch types, diverse sizes, and blending forms of multi-layer structures, and can choose different barrier materials or green materials according to the requirements of products. At the same time, advanced color printing technology can make brand patterns, LOGOs, and promotional information expressed more clearly, enabling more personalized expression of the package.

Rich Environmental Protection Options: Recyclable and Compostable Materials are Available

Since sustainable development thinking lies in people’s hearts, versatile packaging helps to implement environment-friendly materials such as mono-material recyclable packaging films, bio-based packaging films, composting packaging materials, etc., to help brands reduce carbon footprints and meet green packaging regulations and consumer environmental protection standards.

Excellent Barrier Properties: Protect Products from Moisture, Oxygen, and Light

Through the multi-layer composite structure, flexible packaging can effectively block moisture, oxygen, odor, and ultraviolet rays, etc., extend the shelf life of foods, cosmetics, and other products, and ensure stable quality. It is particularly suitable for products with special freshness, hygiene, and safety requirements, such as coffee, milk powder, pet food, and toiletries.

Enhance Shelf Appeal: High-quality Printing Helps Brand Communication

Flexible packaging supports high-definition flexographic printing, gravure printing, digital printing and other processes. Not only are the colors full and the details clear, but also matte, gloss, local light, metal film, transparent window and other effects can be added to enhance visual impact. The unique appearance design helps to stand out in a competitive retail environment and strengthen brand memory points.

Is Flexible Packaging Eco-Friendly?

Yes. Compared with traditional rigid packaging (glass containers, iron cans, hard plastic packaging), flexible packaging generally will use less raw materials, is lighter, has a smaller shape, emits fewer carbon units, and produces less waste to be transported. Even more so if green materials are used, now flexible packaging has become the solution of many companies to shift their direction toward sustainable packaging.

Common types of environmentally friendly flexible packaging include:

Recyclable Flexible Packaging: Using a single material structure (such as pure PE, pure PP, etc.), it is convenient for terminal recycling system sorting and reuse, and is the current mainstream environmentally friendly packaging solution. Suitable for dry goods, snacks, daily chemical products and other categories, it is both environmentally friendly and has good barrier properties.

Compostable Flexible Packaging: Using plant-based biodegradable materials (such as PLA, PBS, PVA, etc.), it can be naturally degraded into carbon dioxide, water and organic matter under industrial or home composting conditions, with zero pollution. Suitable for high-end brands that focus on environmental protection, coffee packaging, organic products, etc.

Biodegradable Flexible Packaging: Part of the flexible packaging is produced from plastic materials with degradation aids incorporated into them, which can be degraded slowly under specific environments (e.g., light, water, and microorganisms), reducing the environmental burden. Though not as fully degraded as compostable materials, it is also a temporary environmentally friendly option for some applications.

Stanley: A Reliable Manufacturer for Custom Flexible Packaging

Stanley is a veteran flexible packaging factory concentrating on customized packaging pouch solutions with advanced equipment, abundant industry knowledge, and utmost commitment to green development. We provide various packaging pouches, including stand up pouches, spout pouches, flat bottom pouhces, roll stock packaging films, and more eco-friendly recyclable pouches, etc., which are widely used in food, pets, personal care, home cleaning, and other products.

We use the RTO thermal storage oxidation system to effectively purify organic waste gas in production, reduce VOC emissions, and further improve environmental standards as a whole. We continuously optimize the material structure and actively utilize recyclable, compostable and degradable film materials to provide customers with greener packaging.

Stanley always bears customer-centricity in mind from structure design, print and lamination, material selection to finished products delivery, and is committed to creating flexible packaging products that are not only functional and key-catching, but also eco-friendly. Choosing Stanley means choosing a trustworthy flexible packaging partner to make your brand stand out in the fiercely competitive market.